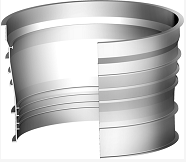

Fan casing is mainly made of titanium alloy, with high hardness, high strength, corrosion resistance, high temperature resistance,causing severe tool wear and work-hardening, difficulty in cutting.

Fan casing is mainly made of titanium alloy, with high hardness, high strength, corrosion resistance, high temperature resistance,causing severe tool wear and work-hardening, difficulty in cutting.

Fan casing mostly involves turning operations. The application of special tools and high pressure cooling cutting tools is an effective way to improve machining efficiency.

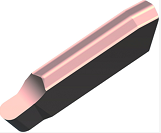

-NF geometry: Sharp nose, for finishing and thin-walled parts machining

-NGF geometry with balanced nose sharpness and strength, is the first choice for semi-finishing to finish

-NM geometry with good edge strength, for continual, interrupted cutting to demanding operations.

-SNR geometry is suitable for operations with large cutting depth and machiningof hard shell of forging.

The above geometries,combined with YBG102 / YBG105 / YBG212 PVD coating, are widely applied infinishing, semi-finishing and roughing in high temperature alloy and titaniumalloy.

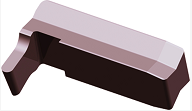

Arc straight headslot milling cutter

Precision grinding, convex v-shaped grinding locatingsurface, accurate positioning, convenient clamping, small head diameter tolerance,suitable for narrow slot milling and back chipping

Precision special grooving milling cutter, dedicatedto slot milling with poor accessibility and back chipping. Tailor made optionsdesigned to individual requirements are available.

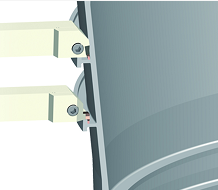

High pressure cooling tools

With high pressure and accurate positioning, thecoolant liquid flows between the edge and chips and separates them, effectivelyreducing the cutting heat in cutting area, increase chip brittleness for betterchip breaking performance, quickly clearing the chips off the insert surface.

Advantages: improve tool life and cutting efficiency, improve chipcontrol to meet the quality requirements.